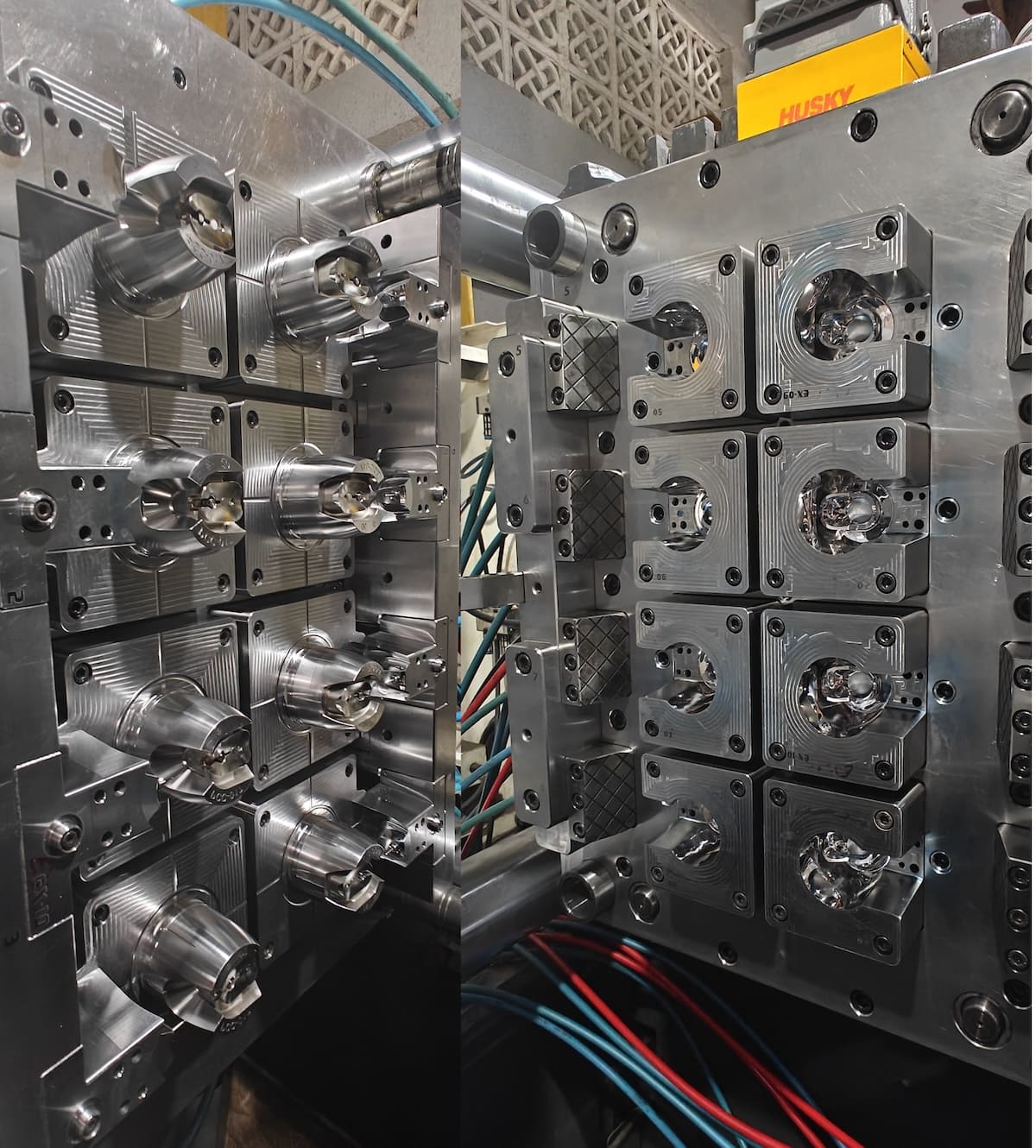

JAP Engineering established in 1990, specializes in the design and manufacturing

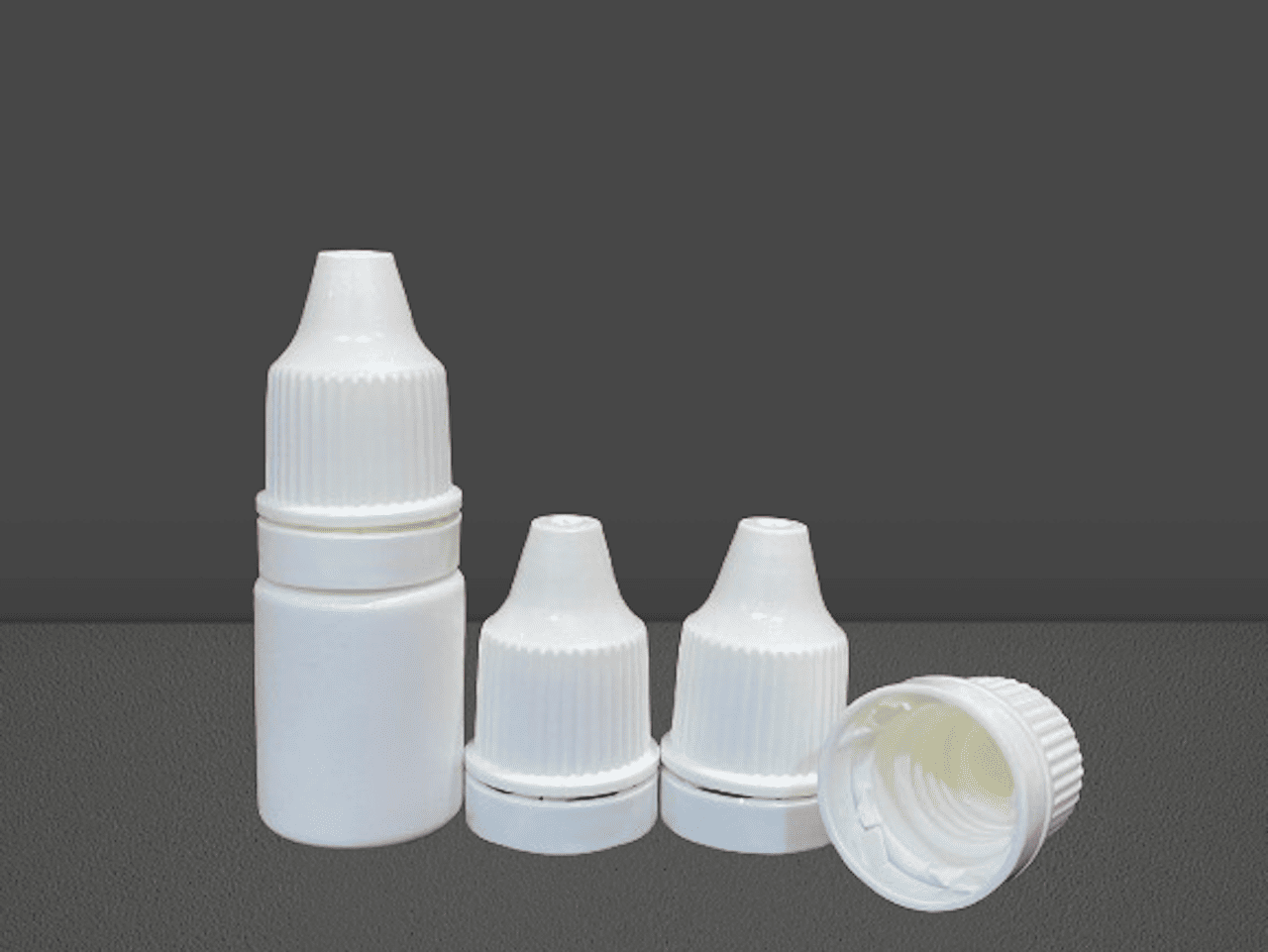

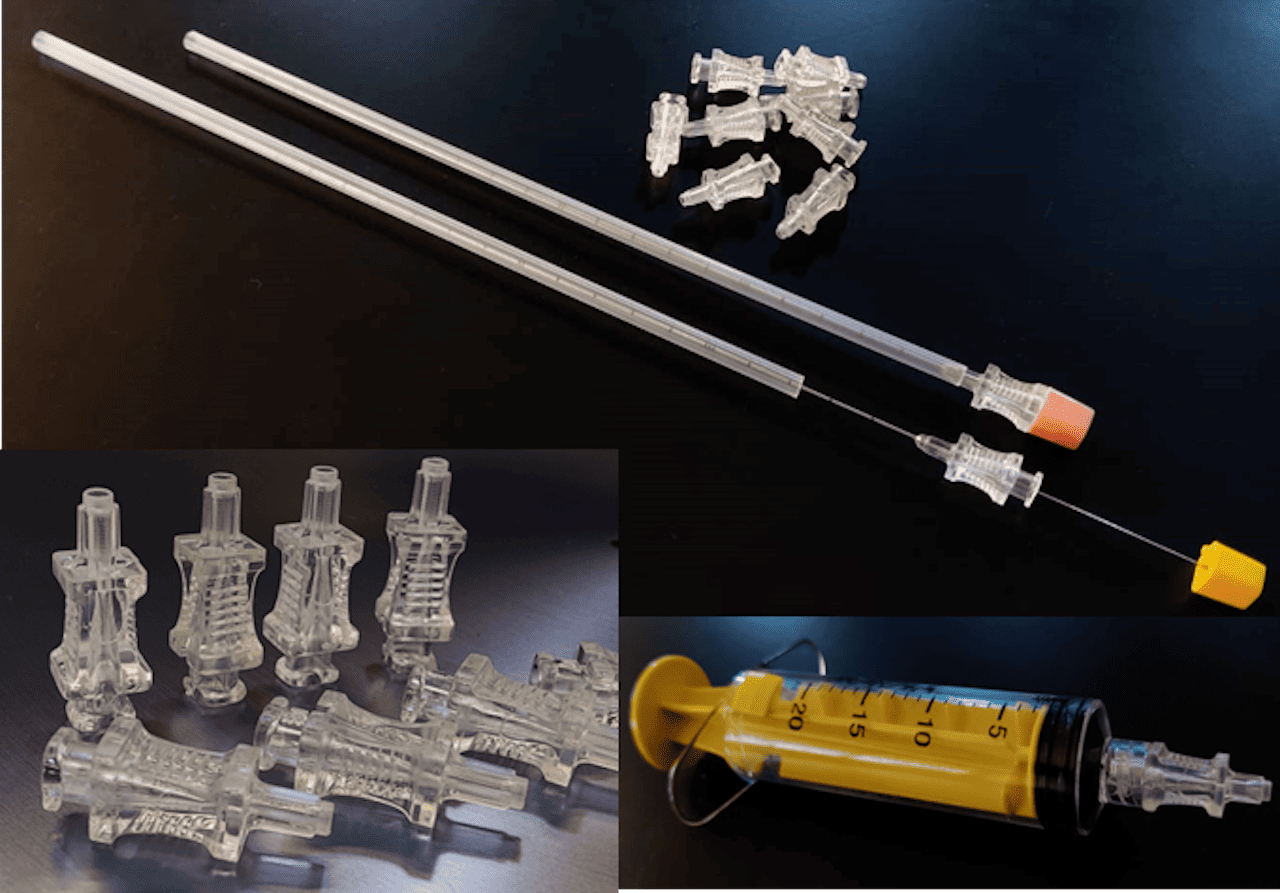

of high precision multi-cavity plastic injection molds for caps and closures.

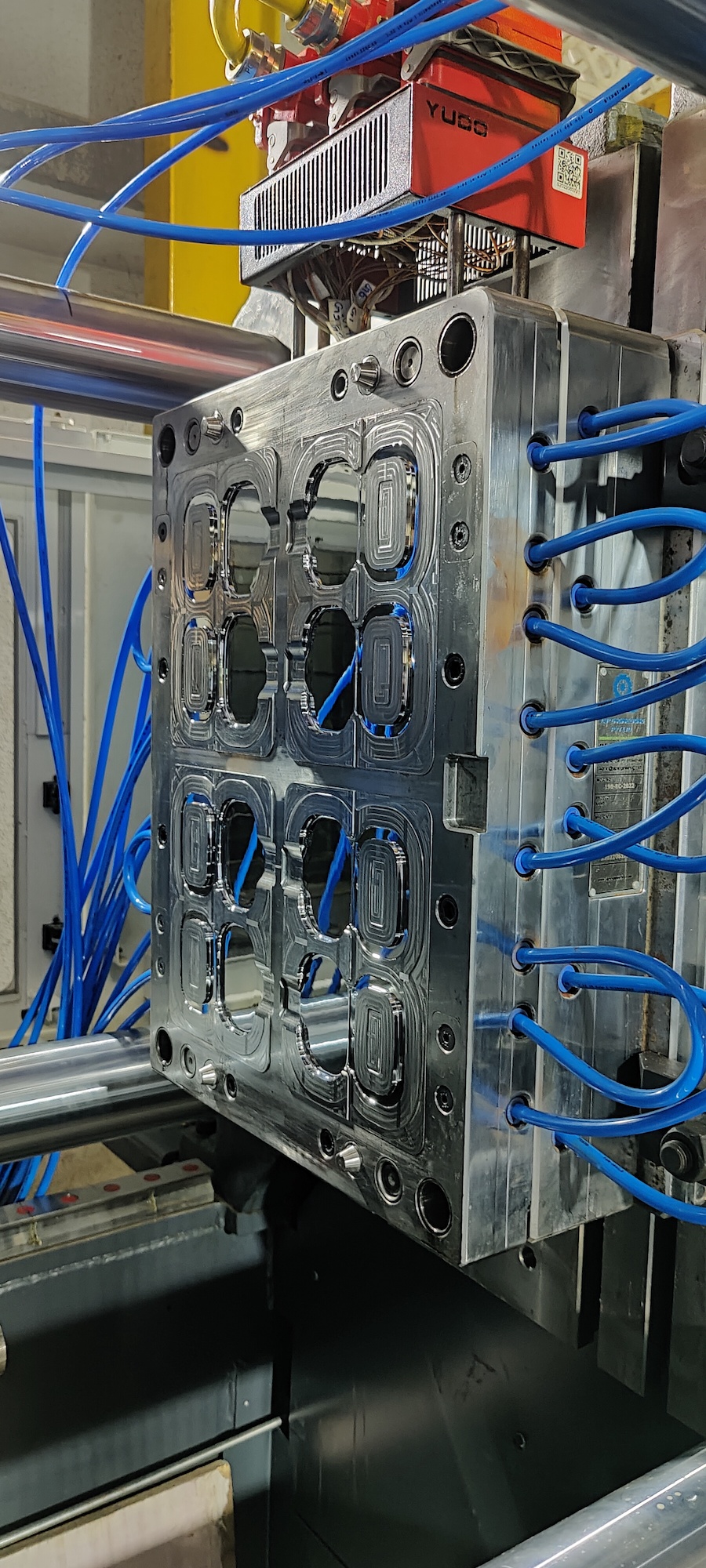

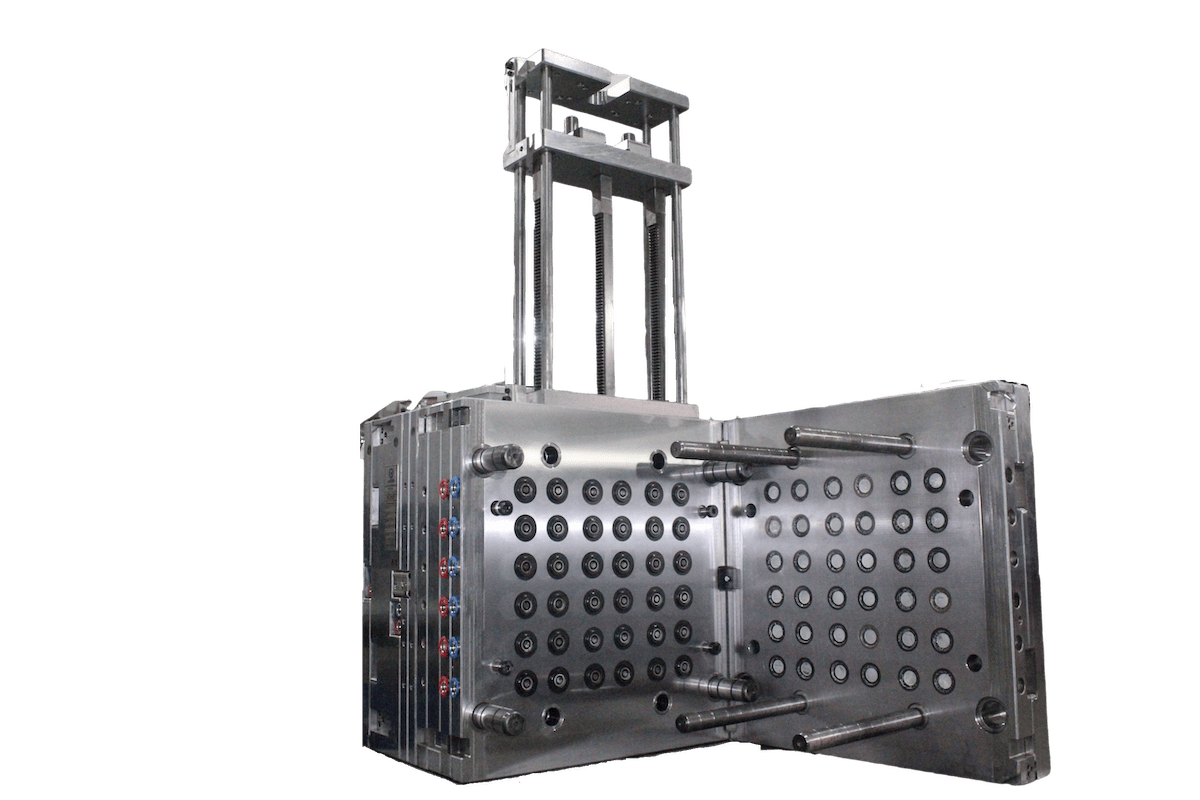

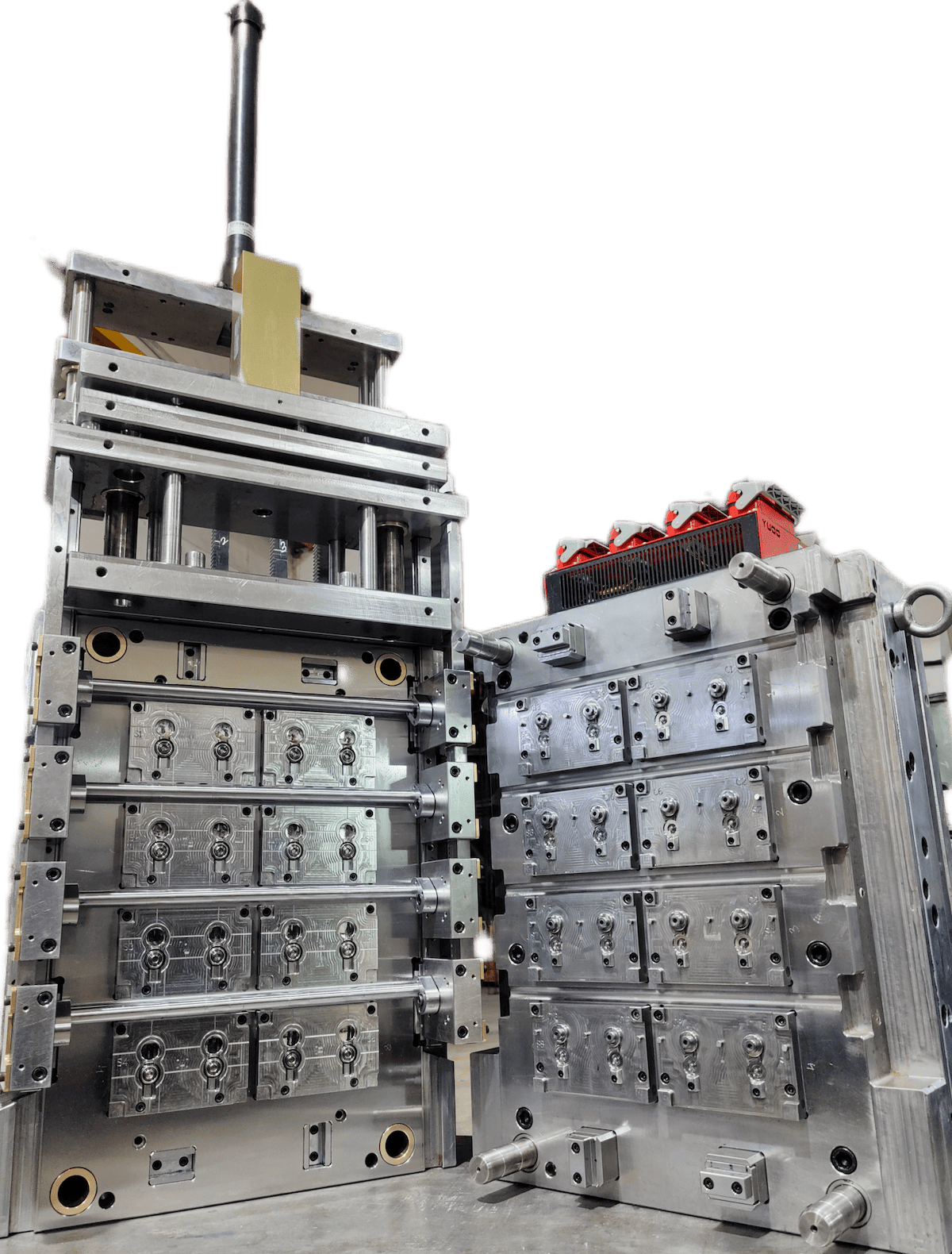

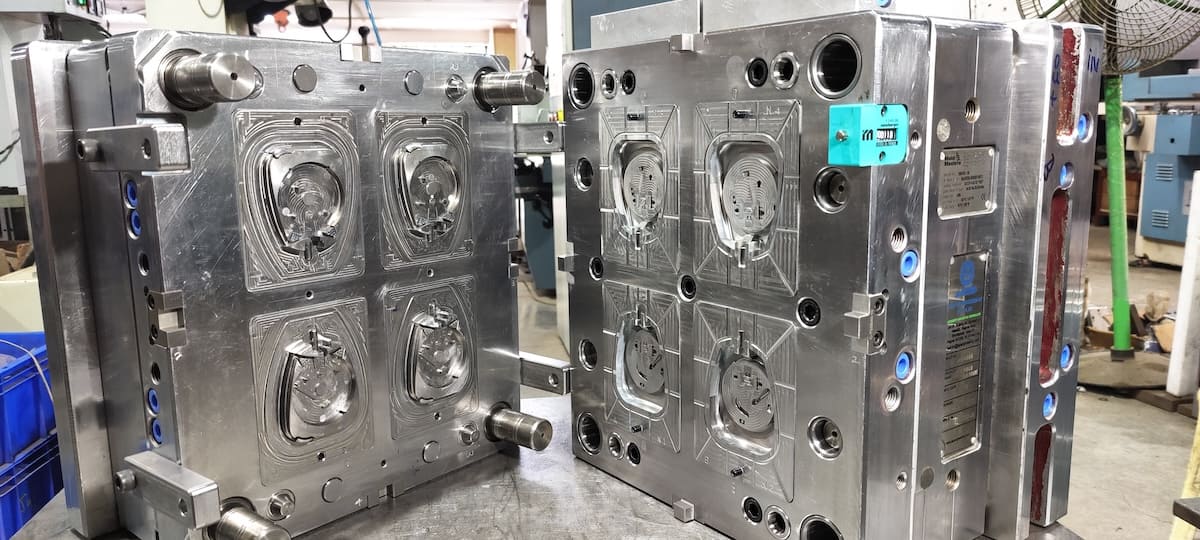

For over 30 years the JAP name stands for Integrity, Innovation, and sophisticated Technology. JAP Engineering specializes in the design and manufacture of high precision multi-cavity geared injection Moulds both hot runner and cold runner for plastic caps and closures. And these high-performance moulds are expected to run anywhere between 2-5 million cycles. JAP has been applying its expertise in design and development for manufacturing top-quality injection Moulds that service various industries. With a strong team, top-of-the-line infrastructure, and passion for perfection JAP ensures to deliver precision mould on time.

We’ve Collaborated with the best in the business.

JAP aims for perfection in manufacturing moulds. This is possible with the experienced in-house design and engineering teams backed by worlds class machines from the best like Makino, Mazak, Milacron, Toshiba, etc. JAP has an annual capacity of around 84 high-precision moulds.

Multi Cavity moulds of upto 96 cavities with high performance tools.

Advanced Mould technologies with artificial runner balancing

Products with very high demand for gloss with finesse

Agro Chemicals and Oils & Lubes, Food and Beverages

We value our customers and that is evident from the bonds we have built with our customers over the years. At JAP we understand the real needs and constraints at the client location and we extend the following various services.